2020 Good Quality Plastic Injection - Fan back cover – Chapman

2020 Good Quality Plastic Injection - Fan back cover – Chapman Detail:

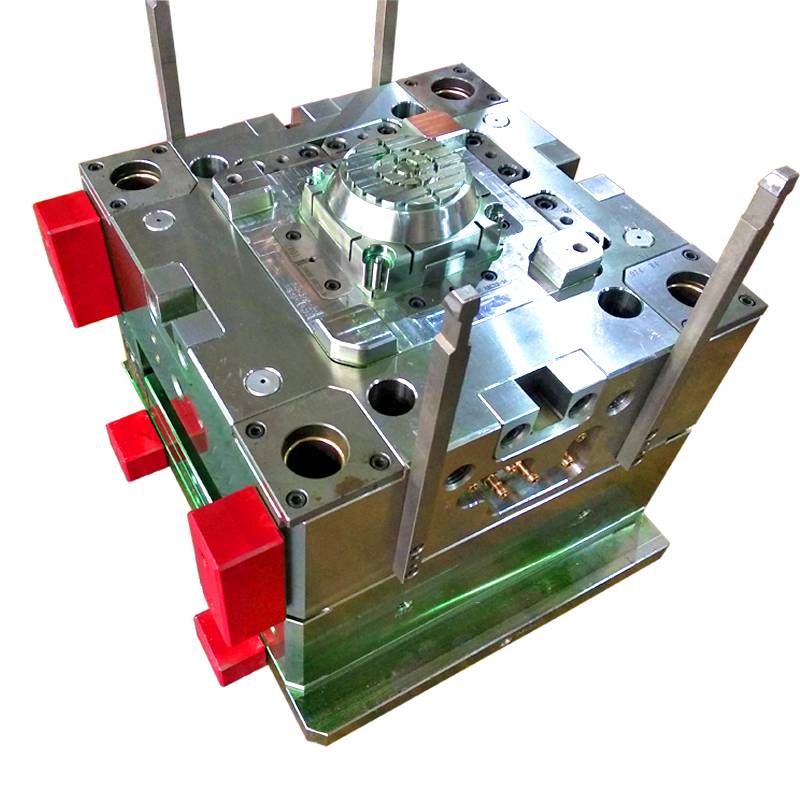

| Mould NO. | CPM-150226 |

| Surface Finish Process | VDI-33 |

| Plastic Material | PA66+30GF |

| Part weight | 30.5g |

| Design Software | UG |

| Part size | 190*190*63 mm |

| Customized | Customized |

| Application | Appliances |

| Mould size | 400 * 400 * 411mm |

| Part Name | Fan back cover |

| Mould Cavity | 1*1 |

| Runner | Three plate mould for point gate |

| Standard | Copy Meusburger |

| Mould Material | 1.2343ESU/1.2312 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 35 days |

| Mould Cycle Time: | 32′s |

| Payment | T T |

Application field

Project Management

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Product detail pictures:

Related Product Guide:

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We're seeking forward in your check out for joint development for 2020 Good Quality Plastic Injection - Fan back cover – Chapman , The product will supply to all over the world, such as: Burundi, Las Vegas, Hamburg, Due to our dedication, our products are well known throughout the world and our export volume continuously grows every year. We will continue to strive for excellence by providing high quality products that will exceed the expectation of our customers.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.

Write your message here and send it to us