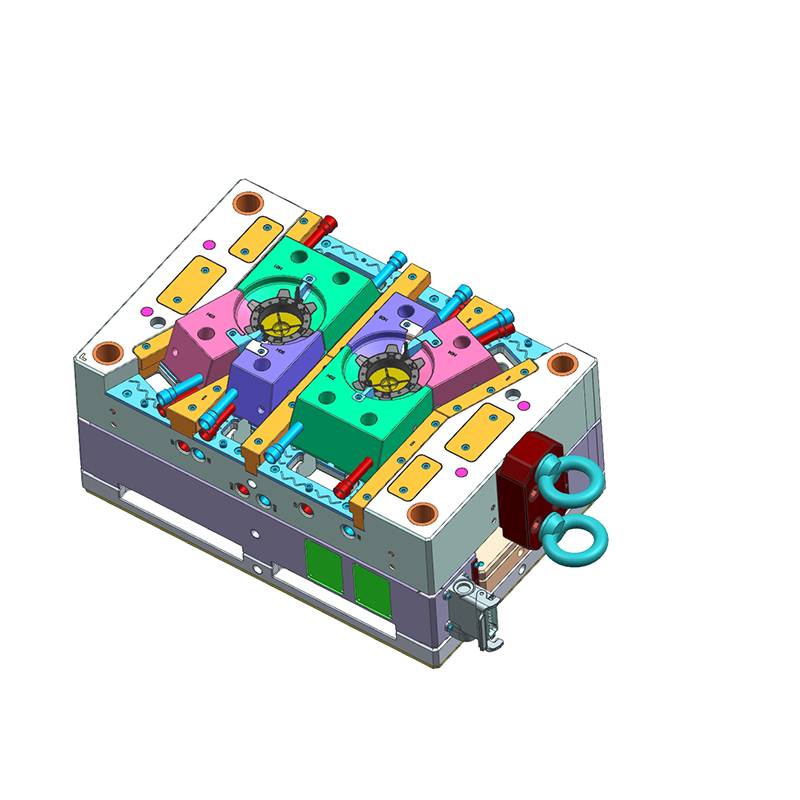

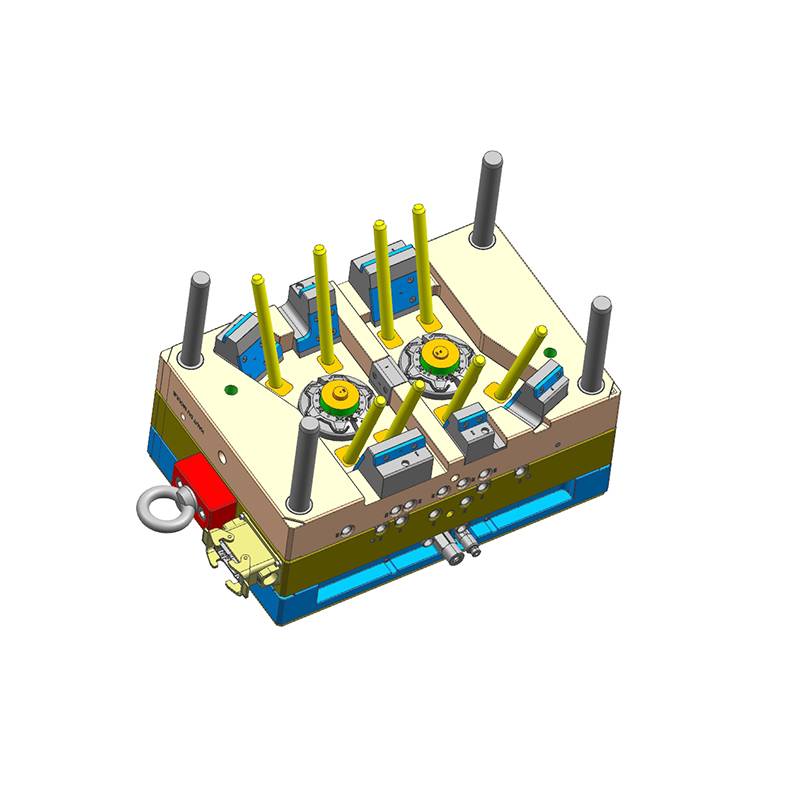

Factory For Custom Mold - Insulating Bobbin – Chapman

Factory For Custom Mold - Insulating Bobbin – Chapman Detail:

| Mould NO. | CPM-150216 |

| Surface Finish Process | VDI-21 |

| Plastic Material | PA4.6 |

| Part weight | 1.2g |

| Design Software | UG |

| Part size | 103.58*103.58*60.62 mm |

| Customized | Customized |

| Application | Automobile |

| Mould size | 396 * 596 * 531mm |

| Mould Name | Insulating Bobbin |

| Mould Cavity | 1*2 |

| Runner | Hot runner for point gate |

| Standard | Hasco |

| Mould Material | 1.2343ESU/1.2312/1.2767 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 45 days |

| Mould Cycle Time: | 12′s |

| Payment | T T |

Project Management

We have 12 Design Engineers with an average of 10 years design experience and a technical college level of education. The team will discuss every new project together and find the perfect solution for it, based on our knowledge and successful experience. We use 3D software to design the mold and Moldflow to verify and optimize the design, so that we can ensure it’s success.

After receiving your PO and part print, we will discuss and recommend any changes we think are necessary to make the part mouldable. We will then provide you with a DFM design report within two days to one week for you to review. We will discuss and then submit the part demoulding method and finalized mould design for your approval, before purchasing and cutting the steel. This process guarantees that we fulfill all of your design requirements.

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Product detail pictures:

Related Product Guide:

We stay with our company spirit of "Quality, Performance, Innovation and Integrity". We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Factory For Custom Mold - Insulating Bobbin – Chapman , The product will supply to all over the world, such as: US, Belgium, Netherlands, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.