factory Outlets for Rapid Prototyping Plastic Injection Molding - Control Unit and Charge Connector bottom cover – Chapman

factory Outlets for Rapid Prototyping Plastic Injection Molding - Control Unit and Charge Connector bottom cover – Chapman Detail:

| Mould NO. | CPM-150239 |

| Surface Finish Process | VDI-36 |

| Plastic Material | ABS |

| Part weight | 231.65g |

| Design Software | UG/CAD |

| Part size | 242*120*98 mm |

| Customized | Customized |

| Application | Appliances |

| Mould size | 450 * 400 * 431mm |

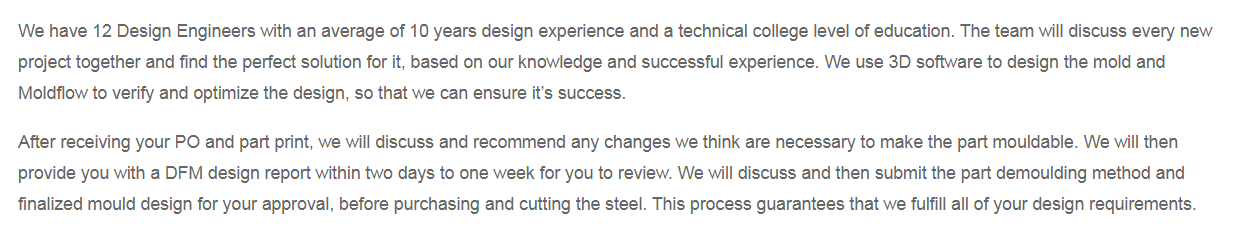

| Part Name | Control Unit and Charge Connector bottom cover |

| Mould Cavity | 1*1 |

| Runner | point gate-three plate mould |

| Standard | LKM |

| Mould Material | NAK80/S50C |

| Mould Life Cycle | 500,000 |

| Lead Time | 35 days |

| Mould Cycle Time: | 42′s |

| Payment | T T |

Application field

Wall Connector continuously checks for the presence of a safe ground connection and automatically recovers from faults. Ground assurance operates by injecting a small amount of current into the ground

conductor in order to measure the impedance between line and ground.

Power sharing circuits may be installed in an electrical panel that supports other loads. If space is limited

or the main power supply is far from the Wall Connectors, installing a dedicated load center may be prudent.

As more Wall Connectors begin plugging into vehicles, the system will automatically distribute power based on the total power allocated to the site.

Project Management

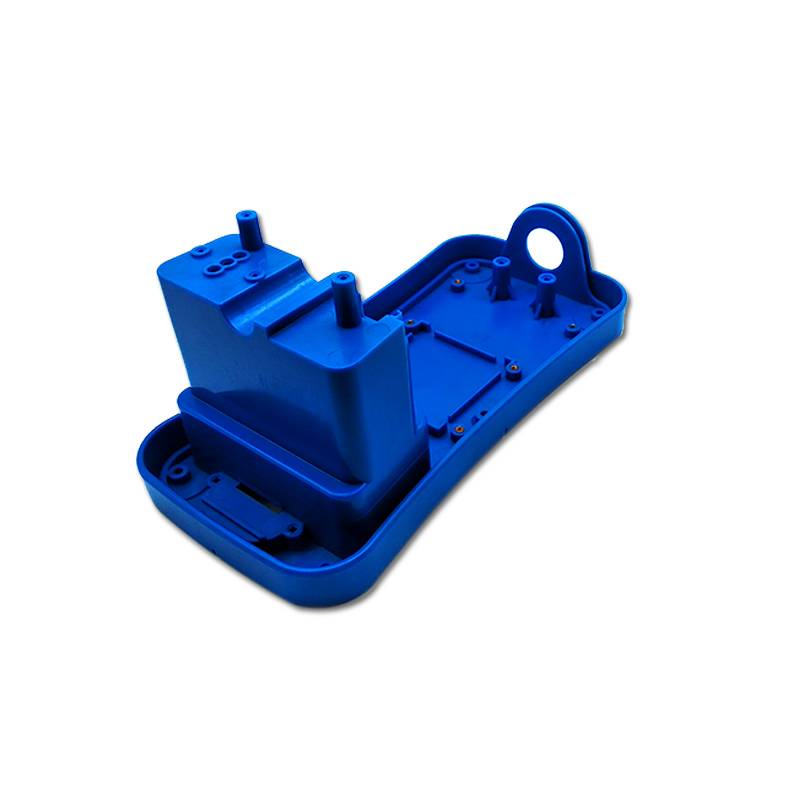

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Product detail pictures:

Related Product Guide:

Our growth depends to the superior products ,great talents and repeatedly strengthened technology forces for factory Outlets for Rapid Prototyping Plastic Injection Molding - Control Unit and Charge Connector bottom cover – Chapman , The product will supply to all over the world, such as: Mauritius, Eindhoven, Indonesia, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we'll be happy to serve you.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.