Factory wholesale Plastic Injection Mold Making - 34 and 4 pin connector – Chapman

Factory wholesale Plastic Injection Mold Making - 34 and 4 pin connector – Chapman Detail:

| Mould NO. | CPM-150220 |

| Surface Finish Process | Polish-#600 |

| Plastic Material | LCP |

| Part weight | 3.5g |

| Design Software | UG |

| Part size | 48.00*14.1*8.2 mm |

| Customized | Customized |

| Application | Connectors |

| Mould size | 250 * 300 * 321mm |

| Part Name | 34 and 4 pin connector |

| Mould Cavity | 1*4 |

| Runner | Cold runner for sub gate |

| Standard | LKM |

| Mould Material | S136/S50C/S-7 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 25 days |

| Mould Cycle Time: | 16′s |

| Payment | T T |

Application field

1.Contacts are machined from solid copper alloy and gold plated;

2.Couplers and receptacle bodies are available in dark anodized aluminum, nylon or stainless steel;

3.Plugs are molded to extra flexible cable to form a one-piece construction;

4.Plugs are furnished with a metal friction ring which prevents deterioration of the rubber and increases pull-out resistance;

5.Receptacles are potted into shell with electrical grade epoxy;

6.Male pins have a molded cork seal at the base of each contact which assures a liquid tight and dust tight fit when units are in use;

7.Keyed to insure proper alignment when engaging male and female units;

8.Ground pin is extended which assures an electrically safe connection because it is the first pin to engage and the last to disengage;

The Connectors and cords won’t warp or deform in this high temperature environment.

Project Management

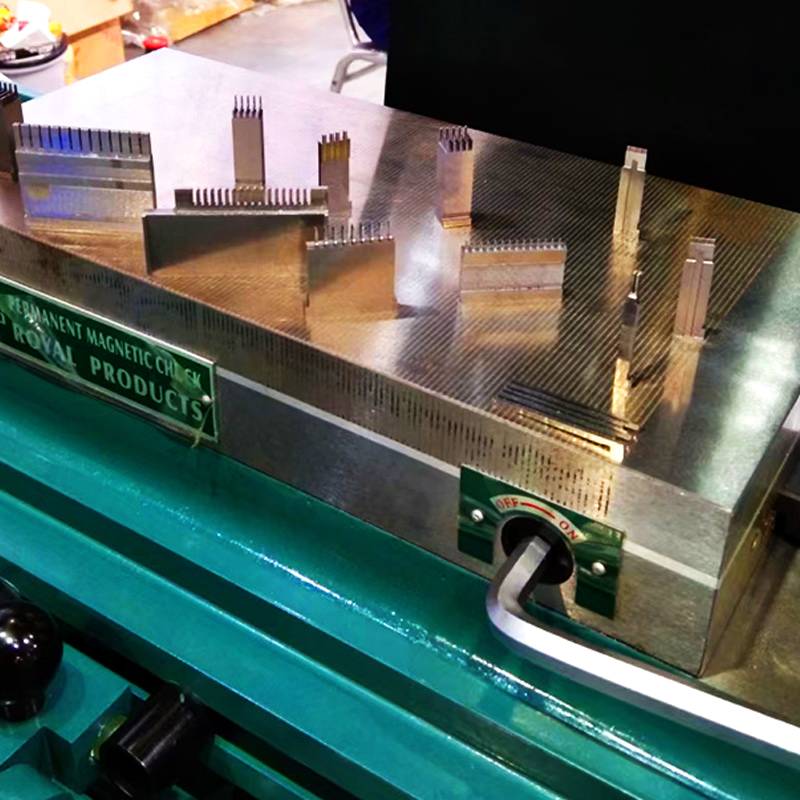

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Factory wholesale Plastic Injection Mold Making - 34 and 4 pin connector – Chapman , The product will supply to all over the world, such as: Norway, Adelaide, Seattle, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we've been likely to be pleased to serve you.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!