Good User Reputation for Plastic Car Part - Medical stress relief guide tube – Chapman

Good User Reputation for Plastic Car Part - Medical stress relief guide tube – Chapman Detail:

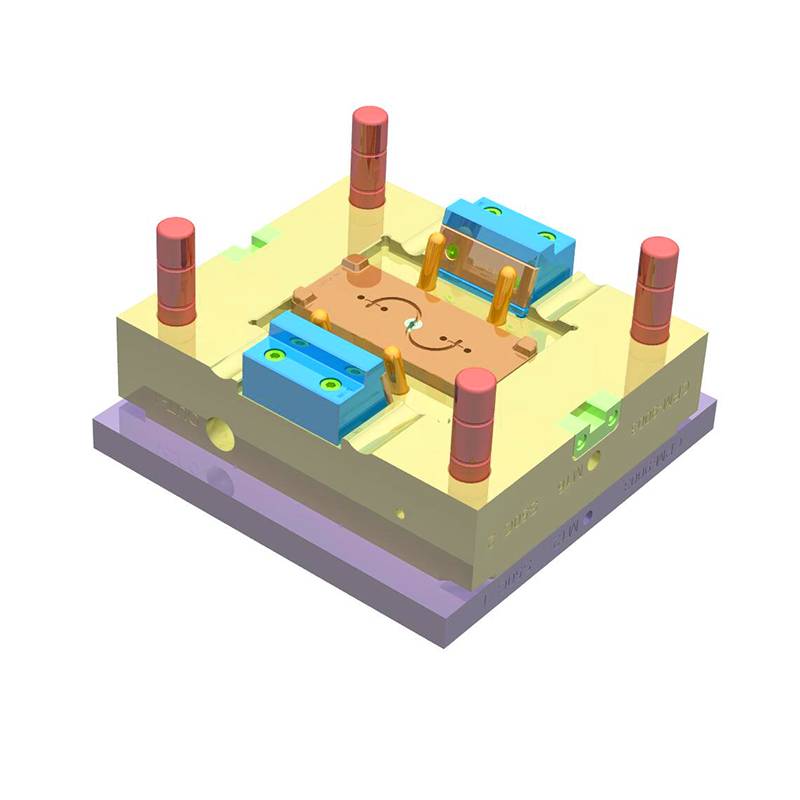

| Mould NO. | CPM-181016 |

| Surface Finish Process | VID20 |

| Plastic Material | PEBAX 35D-50D |

| Part weight | 0.35g |

| Design Software | UG |

| Part size | ø5.00 X 34.00mm |

| Customized | Customized |

| Application | Medical industry |

| Mould size | 246 X 3496 X 317mm |

| Part Name | Medical stress relief guide tube |

| Mould Cavity | 1*4 |

| Runner | Cold runner for sub gate |

| Standard | DME |

| Mould Material | S136(HRC 48-52) |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 25days |

| Mould Cycle Time: | 16′s |

| Payment | T T |

Application field

For labs performing a lot of pipetting on a regular basis, automated liquid handlers offer many advantages. These instruments can improve the reproducibility of your assays while limiting contamination and decreasing the risk of repetitive stress injury. There are many factors to consider when purchasing an automated liquid handling solution include the instrument’s cost, capacity, and ability to meet future needs.

Usually the same supplements that your health care team has prescribed for you to drink can go through the tube. You can use brand-name products and generic supplements that are found over the counter or through your home care or medical equipment company. You can also use specialized tube feeding products depending on your individual needs. Your care team can help you pick the tube and the supplement that is right for you.

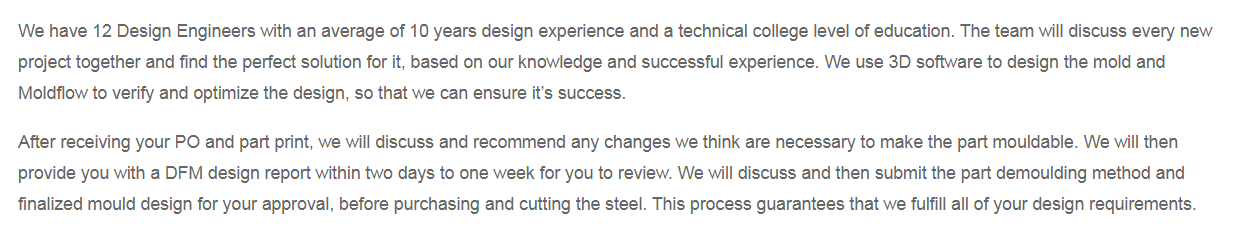

Project Management

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Product detail pictures:

Related Product Guide:

It is a good way to improve our products and service. Our mission is to develop creative products to customers with a good experience for Good User Reputation for Plastic Car Part - Medical stress relief guide tube – Chapman , The product will supply to all over the world, such as: Israel, Hyderabad, Bulgaria, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to offer skilled, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We are going to serve you with all sincerity!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.