Hot Selling for Plastic Moulding Die Design - China 2K Mold Manufacturer – Chapman

Hot Selling for Plastic Moulding Die Design - China 2K Mold Manufacturer – Chapman Detail:

We’ve been proud of your substantial purchaser satisfaction and wide acceptance due to our persistent pursuit of high quality both equally on solution and service for China 2K Mold Manufacturer, Inside our initiatives, we already have a lot of shops in China and our solutions have won praise from buyers all over the world. Welcome new and outdated buyers to contact us to the long run long lasting business relationships.

We’ve been proud of your substantial purchaser satisfaction and wide acceptance due to our persistent pursuit of high quality both equally on solution and service for China Plastic Mould, Injection Mould, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We now have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our goods are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

| Mould NO. | CPM-150217 |

| Surface Finish Process | Polish-#600 |

| Plastic Material | PC+ABS |

| Part weight | 30.5g |

| Design Software | UG |

| Part size | 170.6*65.5*24.5 mm |

| Customized | Customized |

| Application | Electronic appliances |

| Mould size | 400 * 300 * 361mm |

| Part Name | Bank credit card POS machine |

| Mould Cavity | 1*1 |

| Runner | Three plate mould for point gate |

| Standard | DME |

| Mould Material | 1.2343ESU/1.2312/1.2767 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 30 days |

| Mould Cycle Time: | 36′s |

| Payment | T T |

Application field

Project Management

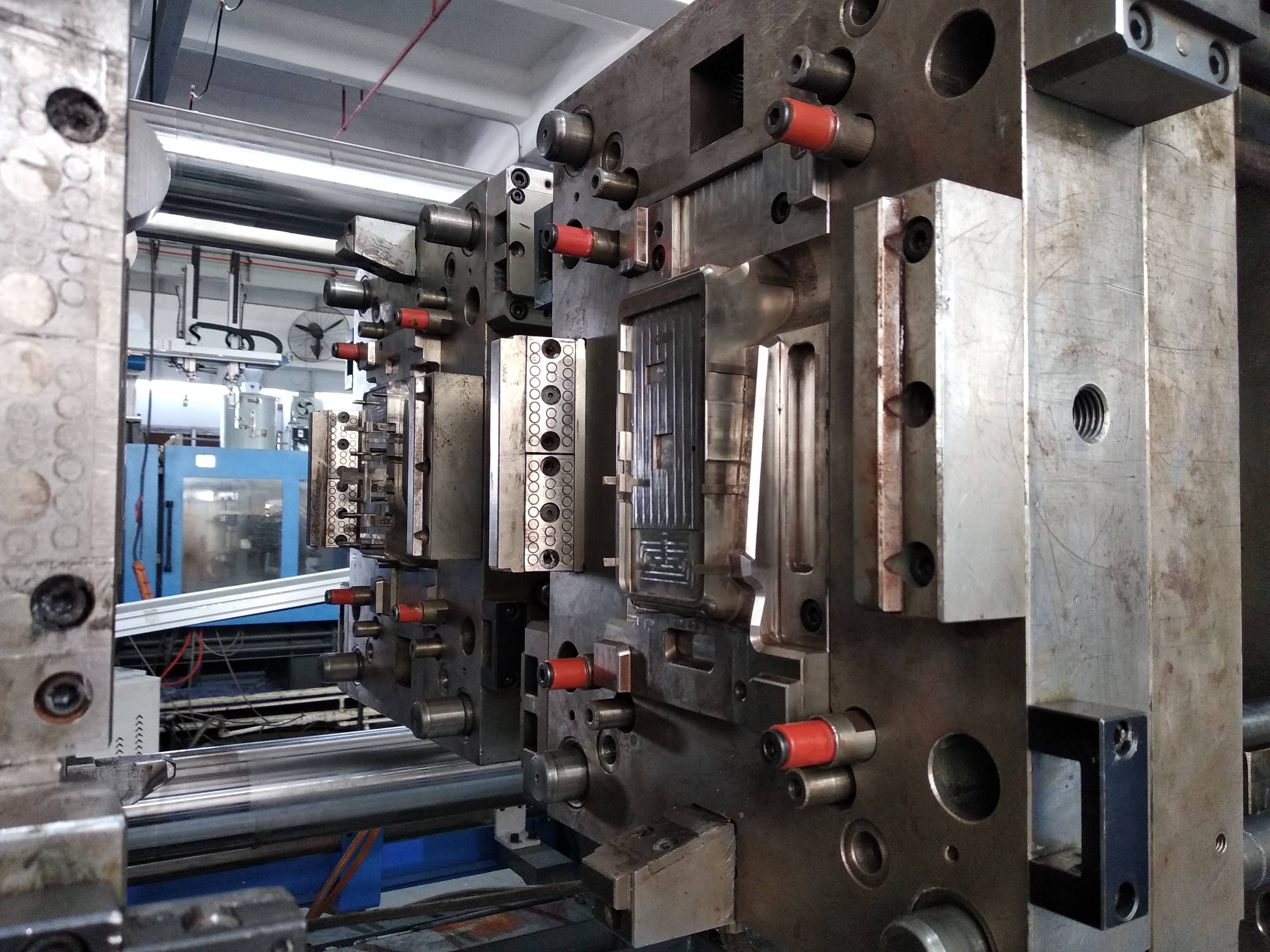

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

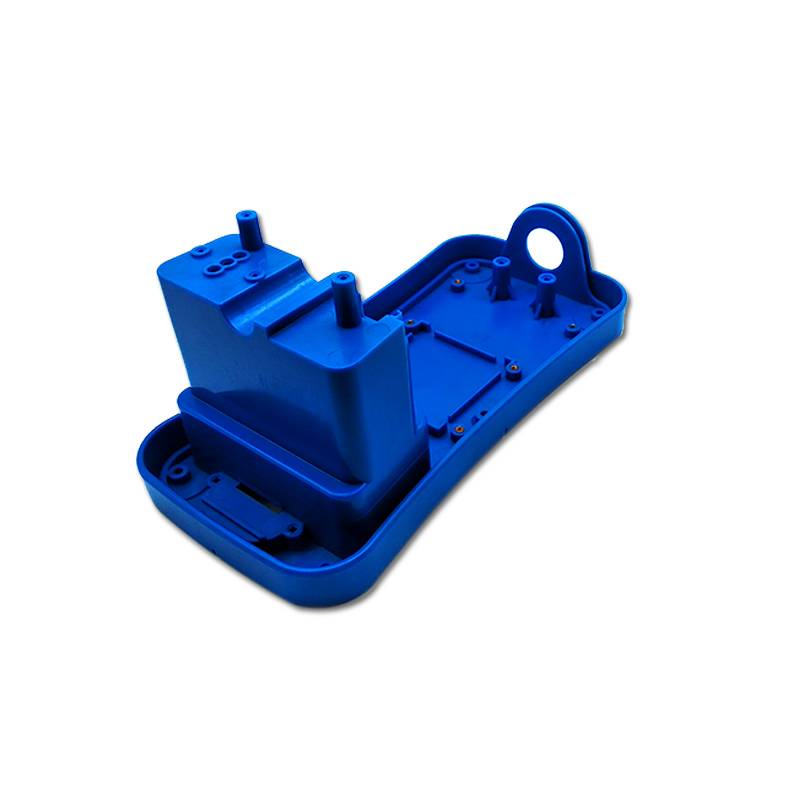

The plastic part of the shell is a part of the credit card POS machine. Its precision is high, and the matching position needs to be made within a tolerance of 0.1mm. Its material is PC+ABS fireproof V0 material.

This shell uses a two-color injection mold, which has very high requirements for mold accuracy and manufacturing. The mold material is NAK80, and the mold production cycle is 36 seconds.

The plastic shell of this POS machine was exported to a POS machine company in the United States. We have made more than 10 different POS machine housing parts for this customer, which have been well received by customers.

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for Hot Selling for Plastic Moulding Die Design - China 2K Mold Manufacturer – Chapman , The product will supply to all over the world, such as: Angola, Jordan, Latvia, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.