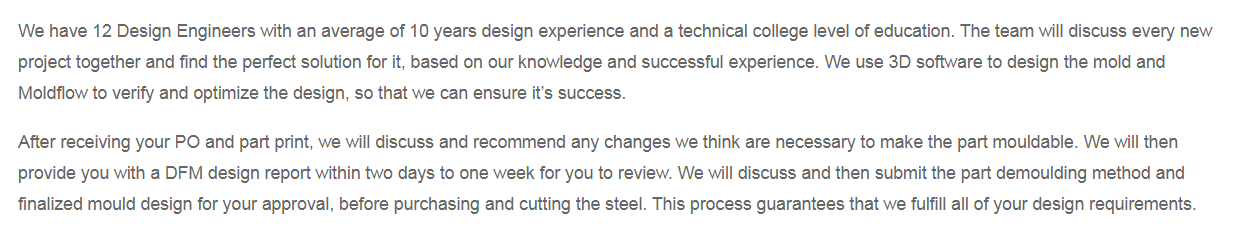

OEM Supply Insert Injection Molding Process - Control Unit and Charge Connector bottom cover – Chapman

OEM Supply Insert Injection Molding Process - Control Unit and Charge Connector bottom cover – Chapman Detail:

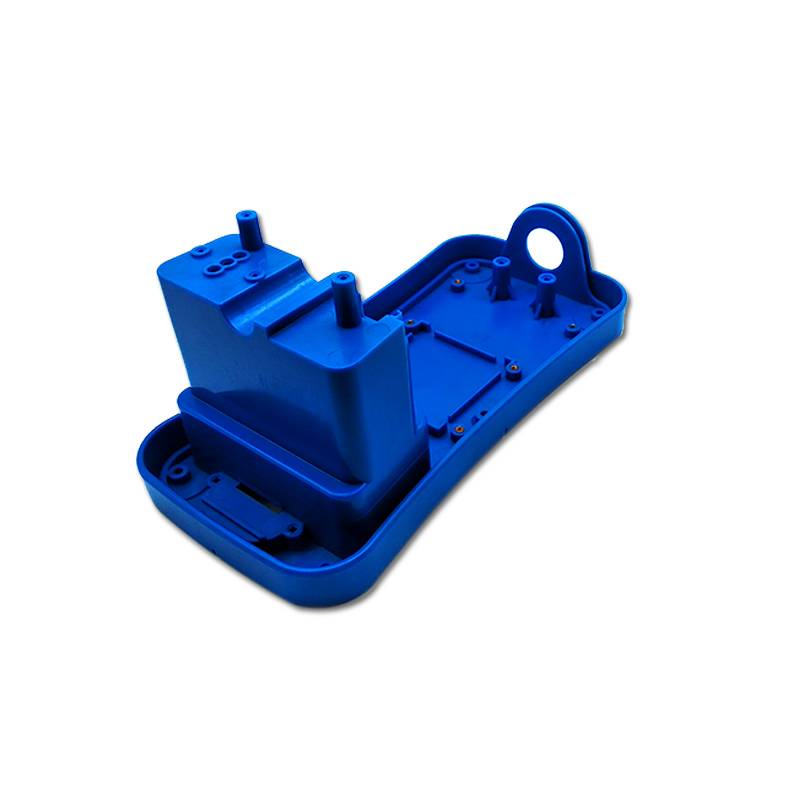

| Mould NO. | CPM-150239 |

| Surface Finish Process | VDI-36 |

| Plastic Material | ABS |

| Part weight | 231.65g |

| Design Software | UG/CAD |

| Part size | 242*120*98 mm |

| Customized | Customized |

| Application | Appliances |

| Mould size | 450 * 400 * 431mm |

| Part Name | Control Unit and Charge Connector bottom cover |

| Mould Cavity | 1*1 |

| Runner | point gate-three plate mould |

| Standard | LKM |

| Mould Material | NAK80/S50C |

| Mould Life Cycle | 500,000 |

| Lead Time | 35 days |

| Mould Cycle Time: | 42′s |

| Payment | T T |

Application field

Wall Connector continuously checks for the presence of a safe ground connection and automatically recovers from faults. Ground assurance operates by injecting a small amount of current into the ground

conductor in order to measure the impedance between line and ground.

Power sharing circuits may be installed in an electrical panel that supports other loads. If space is limited

or the main power supply is far from the Wall Connectors, installing a dedicated load center may be prudent.

As more Wall Connectors begin plugging into vehicles, the system will automatically distribute power based on the total power allocated to the site.

Project Management

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Product detail pictures:

Related Product Guide:

With reliable quality process, good reputation and perfect customer service, the series of products produced by our company are exported to many countries and regions for OEM Supply Insert Injection Molding Process - Control Unit and Charge Connector bottom cover – Chapman , The product will supply to all over the world, such as: Albania, Cyprus, United Kingdom, Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.