OEM Supply Insert Injection Molding Process - Factory Promotional Large Part Molding - Angle buffer – Chapman – Chapman

OEM Supply Insert Injection Molding Process - Factory Promotional Large Part Molding - Angle buffer – Chapman – Chapman Detail:

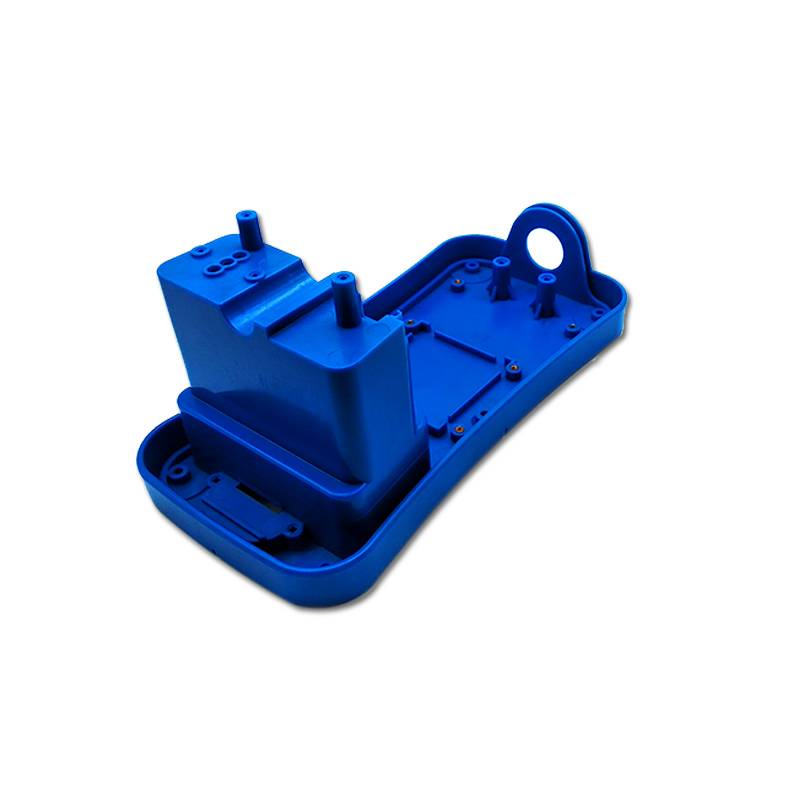

| Mould NO. | CPM-191016 |

| Surface Finish Process | VDI-24 |

| Plastic Material | PA66+30GF |

| Part weight | 13g |

| Design Software | UG |

| Part size | 40.00 X 41.50 X 33.47mm |

| Customized | Customized |

| Application | Automobile |

| Mould size | 246 X 296 X 357mm |

| Mould Name | Angle buffer |

| Mould Cavity | 1*2 |

| Runner | Hot runner for Sub gate |

| Standard | Hasco |

| Mould Material | 1.2344ESR/1.2312/1.2767 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 30days |

| Mould Cycle Time: | 30′s |

| Payment | T T |

Project Management

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of OEM Supply Insert Injection Molding Process - Factory Promotional Large Part Molding - Angle buffer – Chapman – Chapman , The product will supply to all over the world, such as: Armenia, Ukraine, Algeria, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

Write your message here and send it to us