Online Exporter Rapid 3d Printing Service - High reputation China Injection Mold – Chapman

Online Exporter Rapid 3d Printing Service - High reputation China Injection Mold – Chapman Detail:

Our corporation promises all end users in the first-class solutions as well as most satisfying post-sale services. We warmly welcome our regular and new shoppers to join us for High reputation China Injection Mold, At our firm with top quality to start with as our motto, we manufacture products that are entirely made in Japan, from materials procurement to processing. This enables them to get used with confident peace of mind.

Our corporation promises all end users in the first-class solutions as well as most satisfying post-sale services. We warmly welcome our regular and new shoppers to join us for precision custom die tooling manufacturer rapid quality industrial small parts maker making cheap mould plastic injection mold, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our goods have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

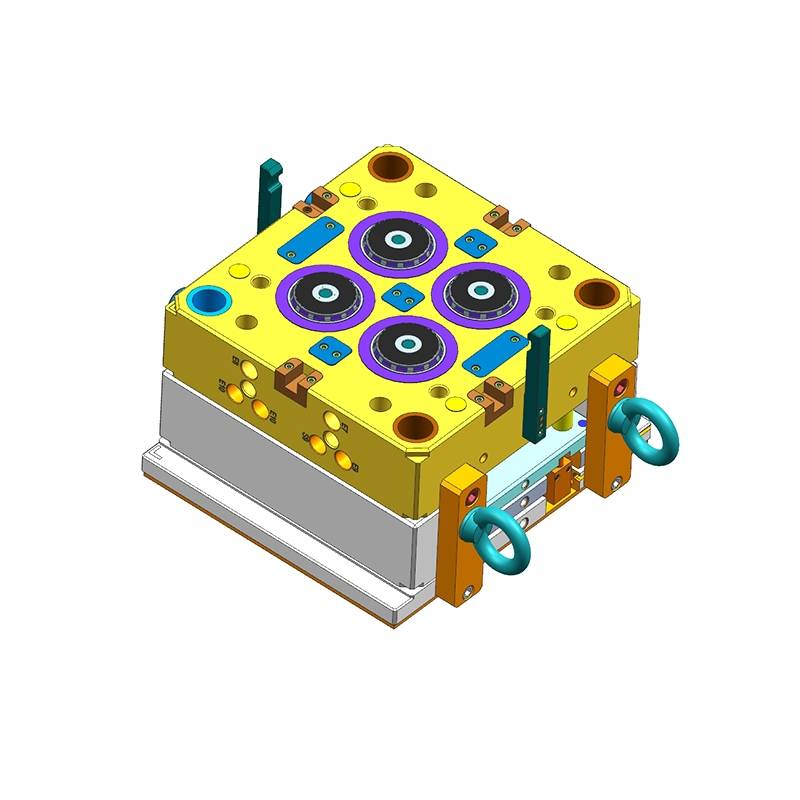

| Mould NO. | CPM-191006 |

| Surface Finish Process | VDI-33 |

| Plastic Material | PA6+30GF |

| Part weight | 17.1g |

| Design Software | UG |

| Part size | 90mm X 90mm X 9.5mm |

| Customized | Customized |

| Application | Automobile |

| Mould size | 400 X 400 X 461mm |

| Mould Name | Oil filters Plastic ccessories |

| Mould Cavity | 1*4 |

| Runner | Cold runner for Point gate |

| Standard | Hasco |

| Mould Material | 1.2344ESR/1.1730/1.2767 |

| Mould Life Cycle | 500,000 |

| Lead Time | 40days |

| Mould Cycle Time: | 38′s |

| Payment | T T |

Application field

While the particle capture efficiency provides important clues on the size of particles the filter can remove (and the stabilized cleanliness of your motor oil), the dirt-holding capacity reveals information about service life, prior to going into bypass.

This is particularly important if you are attempting an extended oil drain and not planning to do a midpoint oil filter change. It’s also important if you drive your car on dirt or gravel roads or in other dusty environments.

Remember, unlike many large diesel engines, automobile oil filters have no indicator to tell you when oil is bypassing and not being filtered. Like the oil change interval itself, the optimum oil filter change interval is largely guesswork, hence the need for a suitable safety margin.

Some materials are lightweight steel, plastic or cardboard. Their ability to stand up to long service intervals, repeated shock loading, vibration, thermal cycles, temperature extremes and changing motor chemistry may be marginal in certain applications and worst-case scenarios.

Many installers, parts stores and even auto makers say the oil filter needs to be replaced only at every other oil change. While you may think you are saving money by this practice, it really is false economy.

The filters on late-model car engines have been downsized to save weight, cost and space. Sometimes they’re hard to find and reach. The quart-sized spin-on filter of the past has been replaced by a pint-sized (or smaller) filter today.

You don’t have to be a genius to figure out that a smaller oil filter has less cumulative dirt-holding capacity and perhaps higher flow restriction – a concern with high rpm’s or low oil temperature engine starts.

However, we have to trust that these smaller filters will be adequate for 3,000- to 7,000-mile oil change intervals; but there is real risk that they will blind off long before a second oil change at 8,000 to 15,000 miles.

If your oil filter becomes plugged before it gets changed, the oil will go into bypass, leading to accelerated engine wear. When your filter goes into bypass, it is no longer working.

While your engine will not be starved of oil, particle concentrations will continue to grow in the oil by as much as 100 times normal levels.

When you have 100 times more dirt, you will have no less than 100 times more wear associated with particle contamination. Sadly, car makers don’t build cars with oil filter bypass alarms.

Project Management

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Chapman maker promises all end users in the first-class solutions as well as most satisfying post-sale services. We warmly welcome our regular and new shoppers to join us for High reputation China Injection Mold , At our firm with top quality to start with as our motto, we manufacture products that are entirely made , from materials procurement to processing. This enables them to get used with confident peace of mind.

High reputation China Injection Mould, Plastic Injection Mold, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our goods have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

Product detail pictures:

Related Product Guide:

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of Online Exporter Rapid 3d Printing Service - High reputation China Injection Mold – Chapman , The product will supply to all over the world, such as: Bandung, Argentina, Angola, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.