Reasonable price Silicone Rubber Injection Molding - Factory supplied China plastic product – Chapman

Reasonable price Silicone Rubber Injection Molding - Factory supplied China plastic product – Chapman Detail:

We’re committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Factory supplied China plastic product, President of our enterprise, with whole personnel, welcomes all buyers to go to our business and inspect. Let us cooperate hand in hand to help make a very good long run.

We’re committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for China Chemical, Insulator, Further, we’re supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to provide our clients an effective range of products.

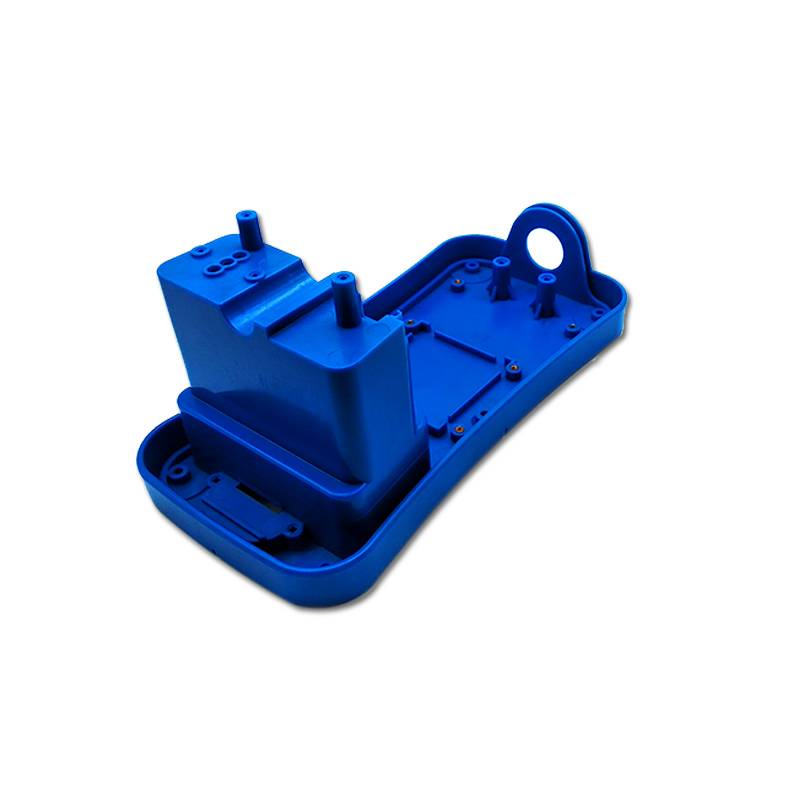

| Mould NO. | CPM-191018 |

| Surface Finish Process | Polish-#600 |

| Plastic Material | PC |

| Part weight | 1.5 g |

| Design Software | UG |

| Part size | 32.00 X 18.50 X 18.1 mm |

| Customized | Customized |

| Application | Electronic |

| Mould size | 296 X 346 X 326 mm |

| Mould Name | Angle buffer |

| Mould Cavity | 1*2(Use exchangeable insert to get four parts) |

| Runner | cold runner for Side gate |

| Standard | Hasco |

| Mould Material | 1.2343/1.2312/1.2767 |

| Mould Life Cycle | 1,000,000 |

| Lead Time | 38 days |

| Mould Cycle Time: | 27′s |

| Payment | T T |

Project Management

We have 12 Design Engineers with an average of 10 years design experience and a technical college level of education. The team will discuss every new project together and find the perfect solution for it, based on our knowledge and successful experience. We use 3D software to design the mold and Moldflow to verify and optimize the design, so that we can ensure it’s success.

After receiving your PO and part print, we will discuss and recommend any changes we think are necessary to make the part mouldable. We will then provide you with a DFM design report within two days to one week for you to review. We will discuss and then submit the part demoulding method and finalized mould design for your approval, before purchasing and cutting the steel. This process guarantees that we fulfill all of your design requirements.

Mould Workshop

Customer visit

Creating value for customers and making it perfect is our philosophy. You will realize greater profits by working together with CPM!

Mould standard

We are experienced in all kinds of steels and fittings of international standard

Packaging&Warehousing

Chapman maker committed to providing one-stop purchasing service of consumer for Plastic project development, plastic molding, welcomes all buyers to go to our business and inspect. Let us cooperate hand in hand to help make a very good long run.

Chapman maker supplied mold, plastic parts for Auto,Medical, Home appliances, IT,Electrical industry. Further, we have our owned team with rich experience from mold design, injection production, assembly.

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for Reasonable price Silicone Rubber Injection Molding - Factory supplied China plastic product – Chapman , The product will supply to all over the world, such as: Spain, Canberra, Israel, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!