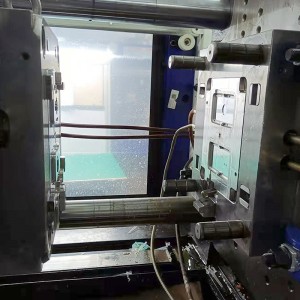

Waterproof plastic case

| Mould NO. | CPM22-C2016 |

| Surface Finish Process | High polishing |

| Plastic Material | ABS-758 |

| Part weight | 30.6g |

| Design Software | UG |

| Part size | 102*61*12 mm |

| Customized | Customized |

| Application | Appliances |

| Mould size | 450 * 350 * 421mm |

| Part Name | Waterproof plastic case |

| Mould Cavity | 1+1 |

| Runner | Banana gate |

| Standard | LKM |

| Mould Material | S136(HRC48-52) |

| Mould Life Cycle | 500,000 |

| Lead Time | 37 days |

| Mould Cycle Time: | 46's |

| Payment | T T |

Application field::

The demand for waterproof technology on electronic devices continues to steadily increase. Not only is the degree of protection important to the developer of the technology, but it remains equally as important to the consumer as well. It is imperative that companies developing waterproof products deliver on their promise. ATEQ’s testing equipment is designed for use in many industries and applications, including testing to ensure product are waterproof, sealed properly, and capable of keeping dust out.

Ingress protection testing tests the degree of protection an enclosure provides against intrusions. One such set of ingress protection tests involves immersing the equipment under test (EUT), in water. These tests are included in the Ingress Protection Code or IP Code ratings as IPX7 and IPX8.

It is a competitive advantage to be able to say that their product is not damaged if it is submerged in water. The term water resistant is frequently used. This marketing push has forced engineers to get creative with the design of enclosures.

What was once accepted is no longer the case. For decades, the expectation was that if an electronic product got wet, it would probably not work. Conventional wisdom stated that if an electronic product got submerged, it would definitely not work. Such is no longer the case.

The Chapman Maker team can provide you with professional guidance and waterproof design advice. If you have similar product development, please feel free to contact Chapman Maker Company.